Supply Chain Intelligence

for SMV'er i Norden

Med vores erfarne konsulentteam og teknologi bygget på best practice får du et strategisk, datadrevet analyse- og beslutningsværktøj.

Vi hjælper handels- og produktionsvirksomheder med at reducere kapitalbinding, optimere lager og skabe fuldt overblik over deres supply chain.

Gør din supply chain til en kommerciel styrke

Hos Inact hjælper vi indkøbs- og supply chain-ansvarlige med at gøre komplekse relationer mellem kunder, produkter og leverandører enkle at forstå og lette at handle på.

Vi gør det muligt for små- og mellemstore virksomheder at reducere kapitalbinding, konsolidere leverandører, optimere kundeprofitabilitet og få fuldt overblik over supply chain.

Den blinde vinkel i supply chain

De fleste virksomheder optimerer på lager, processer og omkostninger.

Men de glemmer den vigtigste dimension: kunden.

Uden indsigt i relationerne mellem kunder, produkter og leverandører træffes

beslutninger i blinde – hvilket betyder:

Produkter bliver udfaset, som vigtige kunder har brug for

Ressourcer bindes i uprofitabel kompleksitet

Salg og Supply Chain taler forbi hinanden

Vækstpotentiale bliver aldrig realiseret

Visuelt overblik - fra kunder til leverandører

Vores løsning samler data fra hele din supply chain og viser, hvordan dine kunder, produkter og leverandører påvirker hinanden. Det betyder, at du kan prioritere indsatser ud fra kundeværdi i stedet for historik og vaner.

På få sekunder kan du se, hvor forretningen skaber værdi, hvor ressourcerne bindes unødigt, og hvor der er potentiale for vækst.

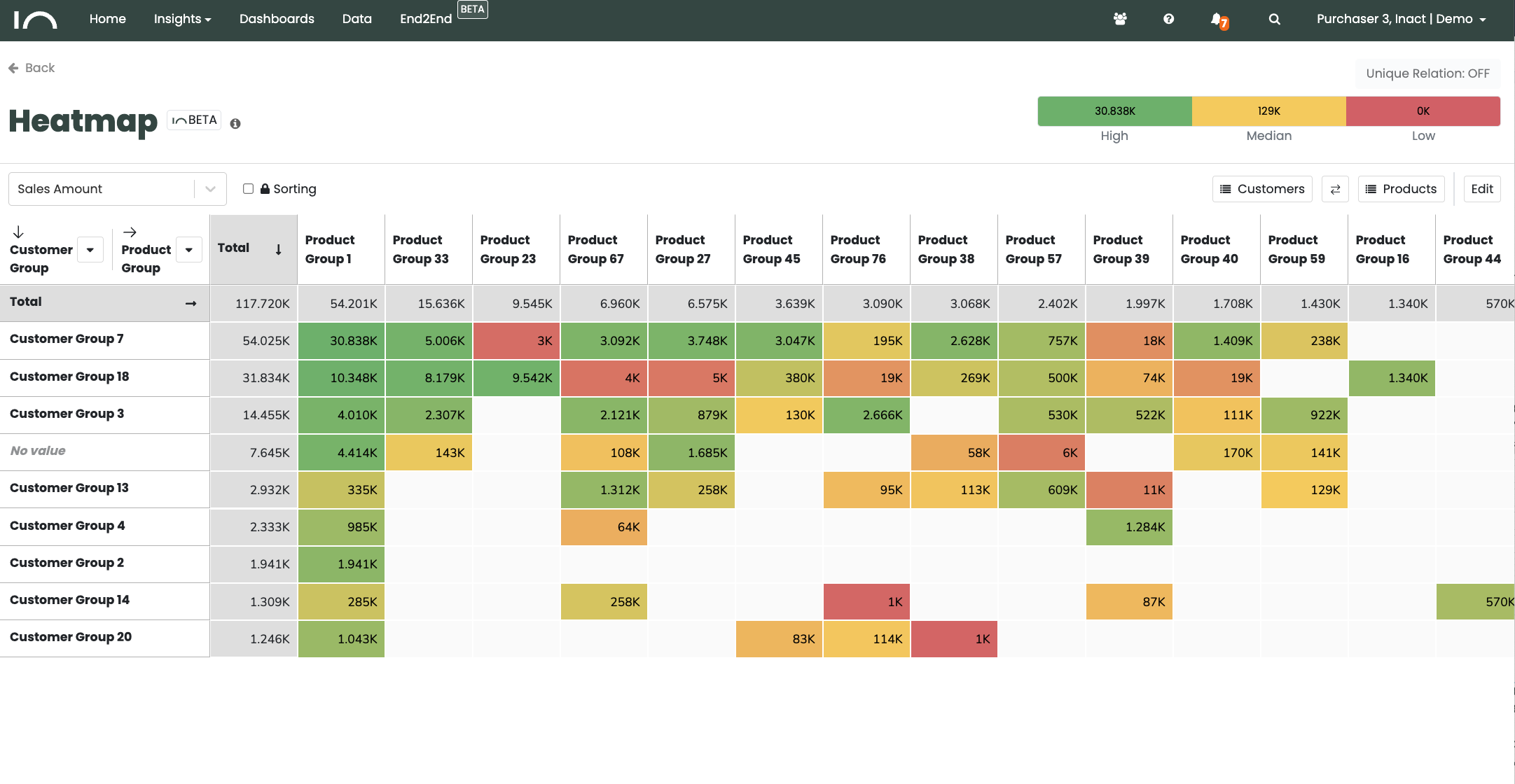

Heatmaps: Se hvor forretningen skaber værdi – og hvor den ikke gør

Få et visuelt røntgenbillede af din forretning.

Med heatmaps ser du straks, hvor værdien skabes, og hvor ressourcer bindes unødigt.

Du kan zoome ind på produkter, kunder og leverandører og opdage mønstre, der tidligere lå skjult i regneark og BI-rapporter.

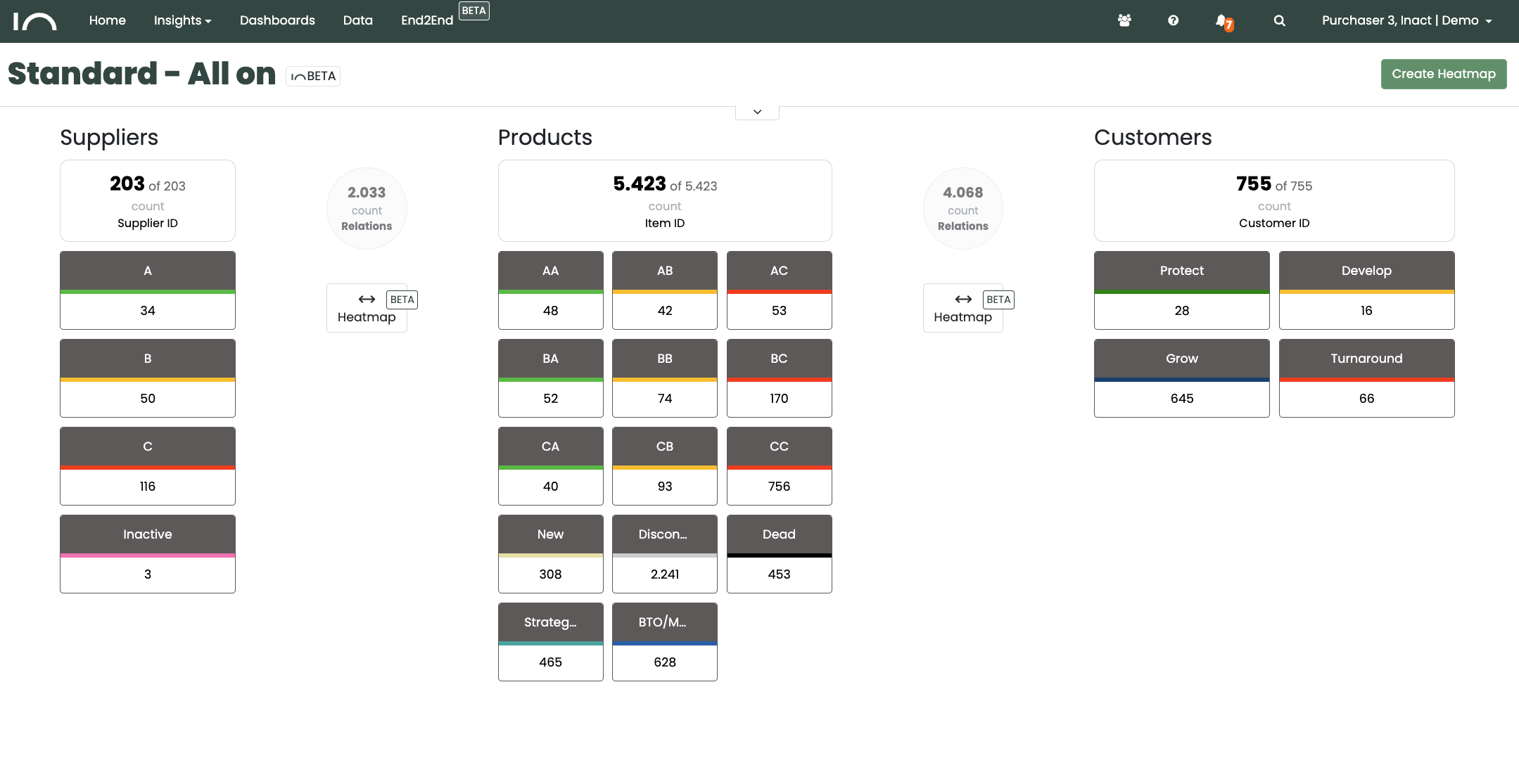

Relationer: Forbind kunder, produkter og leverandører i ét samlet overblik

Se præcist, hvilke produkter dine vigtigste kunder køber, og hvilke leverandører der understøtter dem.

Forstå konsekvenserne, før du fjerner et produkt, køber ind eller skifter en leverandør. Når sammenhængene er tydelige, bliver det lettere at handle i tråd med forretningens strategiske og kommercielle mål.

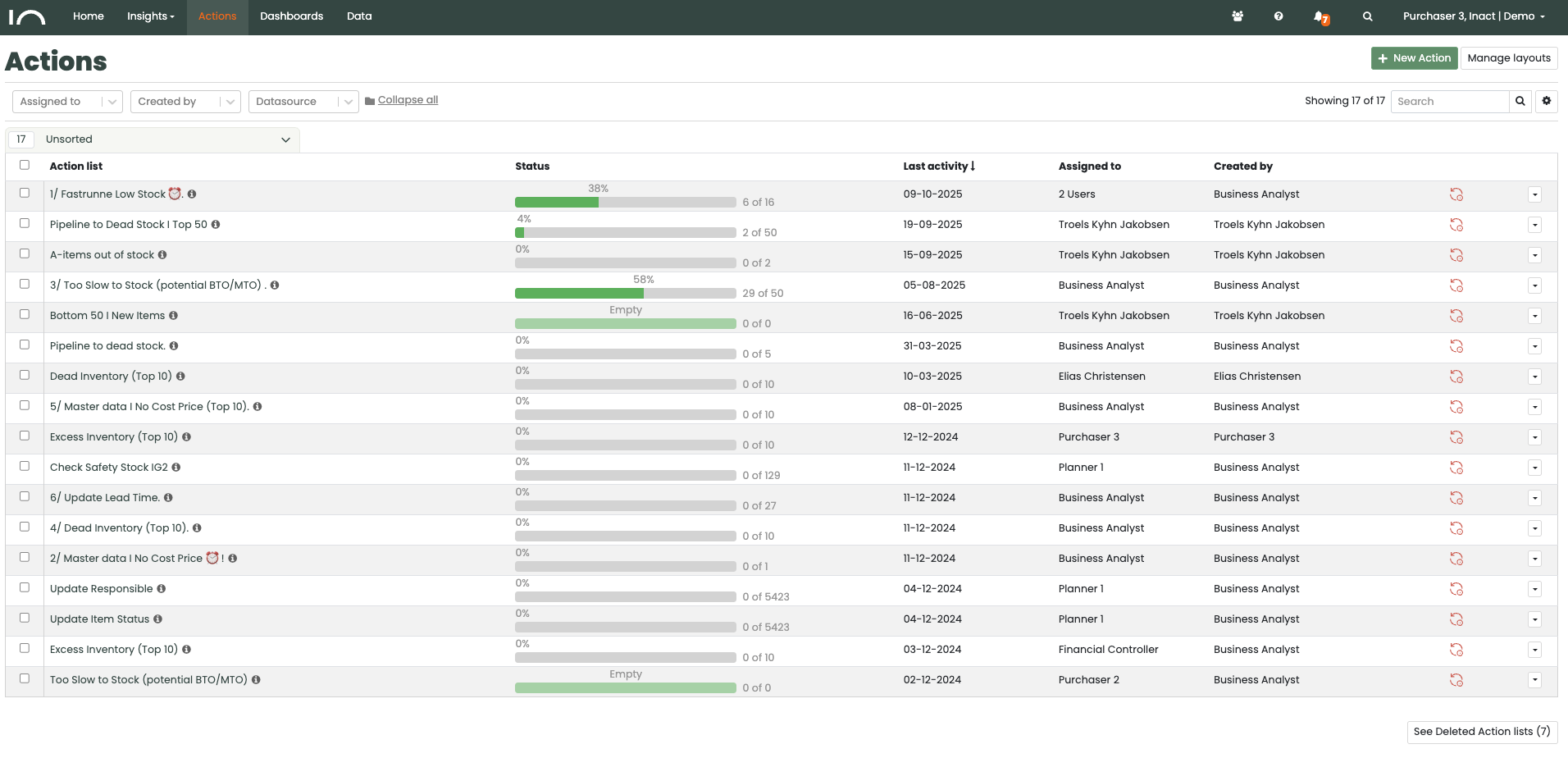

Actions: Omsætter indsigter til opgaver og tjeklister

Platformen hjælper med at prioritere handlinger, så I arbejder på det, der skaber mest værdi, og strategiske beslutninger bliver en naturlig del af hverdagen - ikke bare noget, der vises i rapporter.

Med actions kan du justere sortiment, optimere leverandører og reducere kapitalbinding – alt sammen med få klik.

Hvad vil du opnå først?

At få overblik handler om at starte dér, hvor smerten er størst. Vores løsninger er designet til at give dig kontrol over de fire kerneområder i din supply chain:

Lageroptimering

Reducer kapitalbinding i lageret

Udforsk løsningen

Leverandør Performance

Øg leveringssikkerheden hos leverandører

Udforsk løsningen

Produkt management

Løft marginen på produkter

Udforsk løsningen

End-to-end Intelligence

Skab profitabel vækst med kundefokus

Udforsk løsningen

“Vi får et helt nyt niveau af indsigt. Det gør det muligt at styre langt mere præcist og skabe værdi på tværs af hele forretningen.”

Kevin Welms

Supply Chain Direktør hos Oluf Brønnum & Co A/S

“Det er en brugervenlig løsning, der konstant opdaterer sig selv og hele tiden guider os med konkrete anbefalinger til hvad vi skal gøre.”

Kenneth Krogh Jakobsen

Purchasing Manager hos Elcor

"Det her værktøj, som kan lære os noget om vores sortiment, vores produkter, leverandører og fordelingen af vores forretning, har gjort en kæmpe forskel."

Josefine S. Christensen

Project Manager hos Specific Pharma

Vi gør det nemt for dig

Vi ved, at det kan være tidskrævende og kræve mange ressourcer at implementere ny teknologi og gennemføre interne forandringer. Derfor har vi inkluderet alt, hvad du behøver, for at du kan opnå de bedste resultater uden ekstra omkostninger.

Konsulentteam

Vi sikrer, at løsningen bliver opsat efter jeres behov og er klar til brug. Derudover får I løbende sparring, råd om best practice, teknisk support og opfølgning.

Årlige business reviews

Vi tager medansvar og evaluerer return-on-investment, samt hvordan løsningen understøtter jeres forretningsmål.

Academy program

Klar til at tage din supply chain til næste niveau?

Book en demo og se, hvordan vi kan hjælpe med at omsætte virksomhedens strategi til handling i dagligdagen og gøre det muligt at træffe hurtigere, smartere og mere profitable beslutninger.

Løsningen er til dig, der:

-

Ønsker at prioritere kunder, produkter og leverandører ud fra faktisk forretningsværdi

-

Vil forbinde strategi og drift, så beslutninger understøtter kerneforretningen

-

Har brug for indsigt og overblik, så du kan træffe bedre og hurtigere beslutninger